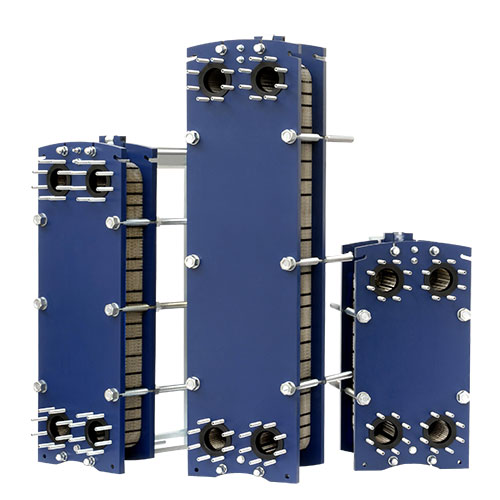

Docal’s gasketed plate heat exchangers have established themselves as an alternative to shell and tube heat exchangers in many fields.

Docal reasserts its expertise as a manufacturer with the ITEX range, the result of long years of technical and thermal development during which nothing was left at random.

Controlled heat exchange

With capacities ranging from kilowatts to a number of megawatts, the particular chevron geometry offers the best compromise between thermal performance (coefficient of heat transfer) and energy efficiency. With the ITEX gasketed plate and frame heat exchangers, you have the full control over the performances.

Scalability

Should the requirements of your application change, a future modulation of power can be easily achieved by adding, changing or removing gasketed plates from your unit.

Customizable

Many materials for the plates and gaskets and many type of connections are available for all models of the ITEX range. The materials, patterns and thicknesses of plates are selected to ensure safety and longevity.

Plate materials

- 304 Stainless steel

- 316L Stainless steel

- 254 SMO

- Titanium (Gr.1)

Gasket materials

- NBR

- EPDM

- EPDM Prx

- FKM VITON®

Connections

- MPT

- Victaulic

- Flange

- Threaded

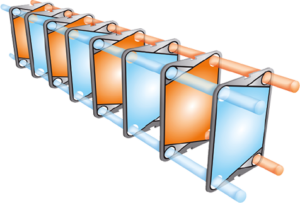

Multiple passes

With their simplicity and easy maintenance, the single-pass exchangers are the industry standard for this type of unit. But Docal also offers configurations with multiple passes to answer the more specific requirements of certain applications. Here’s a diagram illustrating the direction of flow in a single-pass gasketed plate and frame heat exchanger.

Easy-to-use systems

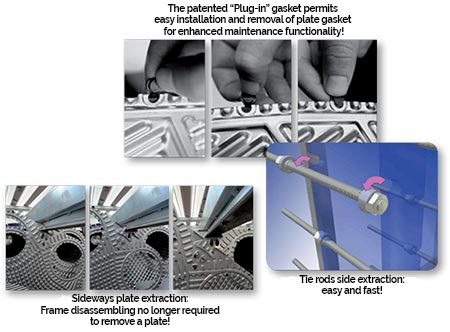

Easy to repair and maintain, the ITEX gasketed plate and frame heat exchangers are amongst the most user-friendly units of the industry. In addition to the clear and well detailed technical manuals, Docal can send a team of qualified technicians to oversee your maintenance. The technological innovations, like patented “Plug-in” gaskets, tie rods side extraction, or auto-blocking bolts system, will surely make the difference in lowering the time and cost of your maintenances.

Plate materials

- Side-removable plates

- Many connection possibilities

- Stainless steel guide bar

- Plateau amovible monté sur rouleau

Gasket materials

- Patented “Plug-in” gaskets

- One-person tightening

- Easy and accurate alignment of plates

- Écrous équipés de roulement à billes

Reliability

Each unit is individually tested before shipment and built according to the highest standards of the industry, like CSA, ASME, ISO and PED. Manufactured with high quality materials, our ITEX range has a high resistance to corrosion. The possibility to clean between the plates, or to replace damaged plates individually, allow the ITEX to efficiently maintain its performance and extend its lifespan.

Economy

The ITEX units are accurately designed for optimized operation. All parts are replaceable, lengthening the unit’s lifetime. With their auto-blocking bolts system, only one person is required for assembling/disassembling the unit. Lateral extraction of the plates and tie rods provide a gain in space. With their compact design, the quantity of fluids circulating in the exchanger is minimized, making this technology a wise choice both economically and environmentally.

Ultra-exact selection

Validated by our partner’s Research & Innovation Centre, our selection software is based on a powerful thermal design engine. The compatibility of fluids and materials is ensured by a continuously enriched database. Docal’s range of plate heat exchangers is highly modular. To determine which models are exactly suited to your needs, our software analyses your thermal needs and allowable pressure losses for fluids. This is primordial during selection as it has an impact on plate selection and, thus, on the heat transfer area. Our software ensures this optimization. The plate exchangers we select are thermally guarantee.

Multiple uses

The ITEX gasketed plate and frame heat exchangers can be used in many type of heating and cooling applications. Here’s a short list of typical applications where a plate and frame unit would be a perfect solution :

Plate materials

- Side-removable plates

- Many connection possibilities

- Stainless steel guide bar

- Plateau amovible monté sur rouleau

Gasket materials

- Patented “Plug-in” gaskets

- One-person tightening

- Easy and accurate alignment of plates

- Écrous équipés de roulement à billes

Docal has an extensive stock of gaskets, stainless steel plates and titanium plates for every gasketed plate and frame heat exchangers model, allowing us to design, build and ship a unit in as low as 24 hours. Need a fast delivery? Call us!

OUR GASKETED PLATE AND FRAME HEAT EXCHANGERS MODELS

You are an agent interested in selling our products, or you are simply looking for additional information? Don’t hesitate to download our brochures. We can also provide, upon request, prints & other promotional material.